Training new control room operators often involves visits to the field to introduce and familiarize learners with equipment and other utility infrastructure. These field site visits are critical to enabling trainees to understand the equipment’s components, how it operates in the field, and how field personnel interact safely with assets. As utilities struggle to coordinate these field visits and make them worthwhile, especially during the pandemic, many are considering alternative options.

Bringing a 3D model into the control room involves following a systematic approach to model development.

Effective utilization of a 3D model for training requires identifying Who, What, When, and How.

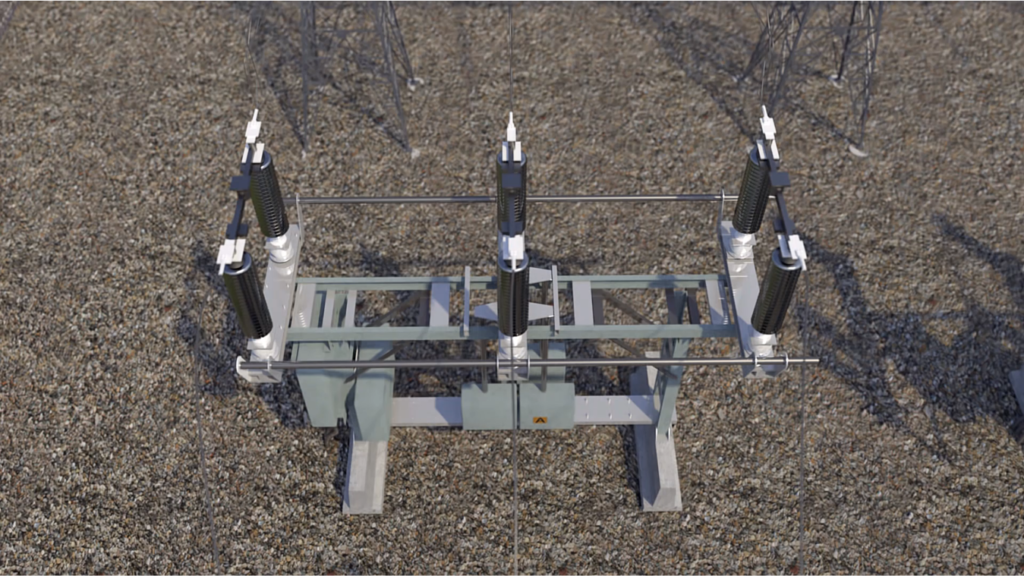

A basic deployment may involve simple 3D images that show a piece of equipment in various configurations and from any angle, such as air-break switches in a substation. In this example, the switches can be safely modeled in 3D to illustrate the open and closed positions without physically touching a device. The same 3D model can be animated to demonstrate physical actions to change the device’s state from one configuration to another. The full benefits of 3D models are realized by enabling their deployment using various methods for different audiences and training needs.