In many control rooms, work processes involved in keeping the meters spinning and lights on have been digitized, integrated, and developed into complex activities over the last two decades.

Before digitization:

As digitization and consolidation of work processes occurred, the need to understand and practice job tasks and duties in a system that replicates as close to real-world conditions as possible became necessary.

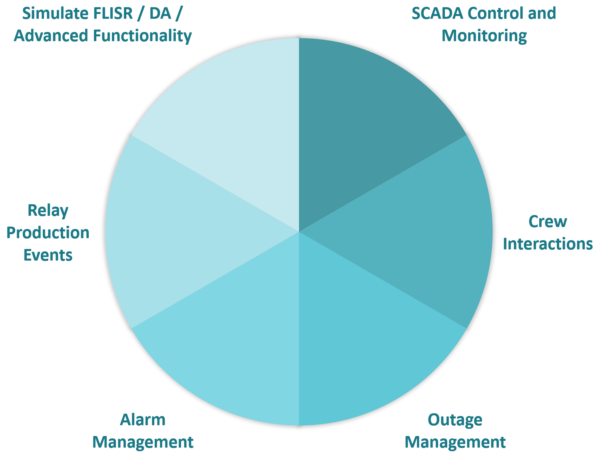

FUNCTIONAL BENEFITS OF AN OTS

An Operator Training Simulator (OTS) provides operations personnel the ability to understand and practice job tasks and duties in end-to-end, role-specific scenarios in a system that replicates as close to real-world conditions as possible.

Users can replay real-world events from the production environment.

OTS READINESS

For new system deployments, there must be an understanding of OTS environment expectations need before training creation, and OTS environments must be functionally ready and available in time to develop end-user training. The following questions are critically important to ensuring environment readiness:

If system functionality configurations are made too late, and training development occurs without those decisions, the simulation quality will be severely limited. If system behaviors differ between OTS and production, or if switching or clearance statements do not look the same in training as they do in production, confidence in and acceptance of both systems will drop.